Introduction

The liquid packaging industry is an essential component of the modern economy, with products ranging from food and beverages to chemicals and pharmaceuticals. The success of this industry relies heavily on the efficient and accurate filling of containers, making industrial filling machines a crucial component of the production process.

This blog post will provide an in-depth look at industrial filling machines, including their definition, types, advantages, key features, and applications. We will also provide a comprehensive guide to help you choose the right industrial filling machine for your specific production needs.

The target audience for this blog post includes business owners and operators in the liquid packaging industry, as well as engineers, technicians, and other professionals involved in the selection and implementation of industrial filling machines. Whether you're a seasoned veteran or new to the industry, this post will provide valuable insights and information to help you make informed decisions about your production process.

What is an Industrial Filling Machine?

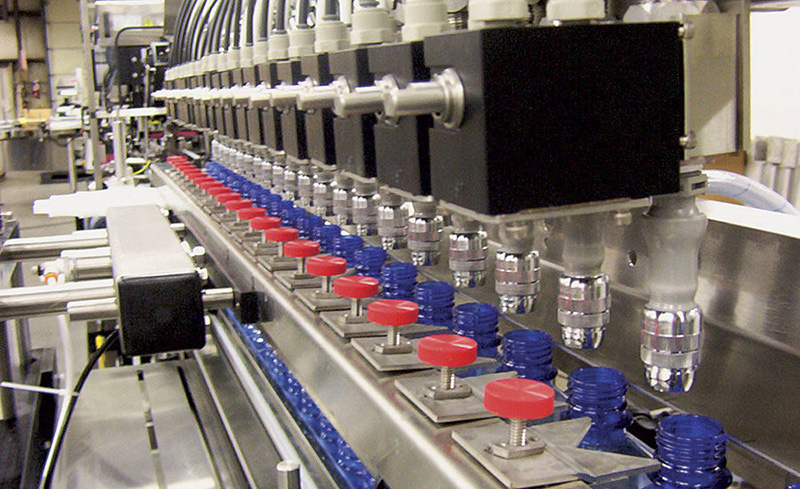

An industrial filling machine is a machine used to fill containers with a specified amount of liquid product. These machines range from manual filling systems to fully automated systems, capable of handling high-volume production needs. The goal of industrial filling machines is to accurately and efficiently fill containers, reducing waste and ensuring consistent product quality.

There are several types of industrial filling machines available, including overflow filling machines, gravity filling machines, pressure filling machines, and piston filling machines. Each type of machine is designed to handle different types of liquids and production requirements.

The choice between manual and automated industrial filling machines depends on several factors, including production volume, product viscosity, and the desired level of accuracy and consistency. While manual filling systems may be suitable for small-scale operations, automated industrial filling machines are more efficient and can handle the demands of high-volume production. Automated industrial filling machines also provide improved accuracy and consistency, reducing waste and increasing the overall efficiency of the production process.

Advantages of Using Industrial Filling Machines

The use of industrial filling machines has several key advantages that make it a valuable investment for businesses in the liquid packaging industry. Firstly, industrial filling machines increase efficiency and productivity, allowing for faster and more accurate filling of containers. This not only increases the overall output of the production process, but also reduces the time and labor required to fill containers manually.

Improved accuracy and consistency are also major benefits of using industrial filling machines. With precise filling technology, industrial filling machines ensure that each container is filled with the exact same amount of liquid, reducing waste and increasing product consistency. This helps maintain the quality of the product and meets the strict standards required by many industries.

In addition to increased efficiency and accuracy, the use of industrial filling machines can also reduce labor costs. By automating the filling process, companies can reduce the number of manual labor hours required, freeing up personnel for other tasks.

Finally, industrial filling machines increase safety for operators. With automated systems, there is no need for operators to handle heavy containers or perform repetitive manual tasks, reducing the risk of injury and improving the overall working environment.

Key Features of Industrial Filling Machines

Precision filling technology is one of the key features of industrial filling machines. With the use of sensors and digital controls, industrial filling machines are able to accurately measure and dispense the correct amount of liquid product, reducing waste and improving product consistency.

Easy operation and maintenance is another important feature of industrial filling machines. With intuitive controls and user-friendly interfaces, industrial filling machines can be operated by personnel with minimal training. Regular maintenance is also simple and straightforward, reducing downtime and increasing the lifespan of the machine.

Versatility in handling different types of liquids is another key feature of industrial filling machines. With the ability to adjust settings and controls, industrial filling machines can accommodate a wide range of liquid products, from thin and runny liquids to thick and viscous liquids. This versatility makes industrial filling machines an ideal solution for businesses producing multiple types of products.

Customizable settings and controls are another advantage of industrial filling machines. With the ability to adjust parameters such as fill speed and volume, industrial filling machines can be tailored to the specific production needs of each business. This allows for a more efficient and effective production process, maximizing the return on investment for businesses.

Applications of Industrial Filling Machines

Industrial filling machines have a wide range of applications, serving industries such as food and beverage, pharmaceuticals, chemicals, cosmetics, and more.

In the food and beverage industry, industrial filling machines are used to fill containers with products such as condiments, sauces, and juices. The accurate and consistent filling provided by industrial filling machines helps maintain the quality and safety of food products, meeting the strict standards required by this industry.

The pharmaceutical and chemical industries also make extensive use of industrial filling machines. With precise filling technology, industrial filling machines are able to dispense the correct amount of medication or chemical product, ensuring the safety and efficacy of these products.

Cosmetics and personal care products are also commonly filled using industrial filling machines. With the ability to handle a wide range of viscosities and dispensing volumes, industrial filling machines are ideal for filling containers with products such as lotions, creams, and shampoos.

Industrial filling machines are also commonly used in industrial and agricultural applications, dispensing chemicals such as pesticides, herbicides, and fertilizers. The accurate and consistent filling provided by industrial filling machines helps ensure the safety and effectiveness of these products.

These are just a few examples of the wide range of applications for industrial filling machines. Regardless of the specific industry, industrial filling machines play a critical role in the efficient and accurate filling of containers, ensuring the quality and safety of the final product.

Choosing the Right Industrial Filling Machine

With so many options on the market, choosing the right industrial filling machine can be a challenge. To ensure that you select the right machine for your business, it is important to consider the specific needs of your production process.

The first consideration when choosing an industrial filling machine is the type of liquids that you will be filling. Different machines are designed to handle different viscosities and dispensing volumes, so it is important to select a machine that is suitable for your specific products.

Another important factor to consider is the speed and efficiency of the machine. Depending on your production needs, you may require a high-speed machine for high-volume production, or a slower machine for more delicate products.

The level of precision and accuracy required is also a key consideration. For industries such as pharmaceuticals and cosmetics, precise filling is critical to ensuring the safety and quality of the final product.

The ease of operation and maintenance is another important factor to consider. Select a machine that is user-friendly and has straightforward maintenance procedures to minimize downtime and ensure long-term reliability.

Finally, it is important to consider the cost and return on investment of the industrial filling machine. Look for a machine that provides the best value for the cost, with features and capabilities that meet the specific needs of your business.

With these factors in mind, you can choose the right industrial filling machine for your business, ensuring an efficient and effective production process.

Conclusion

Industrial filling machines play a critical role in the production processes of many industries, from food and beverage to pharmaceuticals and chemicals. With their ability to provide precise, accurate, and consistent filling, industrial filling machines are an essential tool for businesses looking to improve the quality and efficiency of their production process.

With so many options on the market, it is important to choose the right industrial filling machine for your specific needs. From the type of liquids you will be filling to the speed and precision required, there are many factors to consider when selecting an industrial filling machine.

By taking the time to understand the specific needs of your business and choosing the right industrial filling machine, you can improve the quality of your products, minimize waste, and maximize the return on investment.

Whether you are starting a new business or upgrading your existing production process, an industrial filling machine is an investment worth making. With its ability to provide precise, accurate, and efficient filling, an industrial filling machine is the key to a successful and productive production process.