A plastic bottle filling machine is a machine that automatically fills and seals plastic bottles with a specific liquid or product. These machines are commonly used in the food and beverage industry, as well as in the chemical, cosmetic, and pharmaceutical industries. There are various types of plastic bottle filling machines available, each with its own unique features and capabilities. In this ultimate guide, we will explore the different types of plastic bottle filling machines, how they work, and the factors to consider when choosing the right one for your business.

Types of Plastic Bottle Filling Machines

Gravity Filling Machines:

These machines use the natural flow of gravity to fill bottles with a product. Gravity filling machines are best suited for low viscosity liquids such as water, juice, and wine. They are simple and easy to operate, making them a popular choice for small businesses.

Pressure Filling Machines:

These machines use pressure to fill bottles with a product. Pressure filling machines are suitable for both low and high viscosity liquids such as sauces, condiments, and pastes. They are more precise and accurate than gravity filling machines and are ideal for businesses that require precise filling and dosing.

Volumetric Filling Machines:

These machines use precise measurement to fill bottles with a specific volume of product. Volumetric filling machines are suitable for both low and high viscosity liquids and are commonly used in the pharmaceutical and chemical industries. They are highly accurate and precise, making them ideal for businesses that require precise dosing of their products.

Net Weight Filling Machines:

These machines use a load cell to weigh the product as it is being filled into the bottle. Net weight filling machines are suitable for both low and high viscosity liquids and are commonly used in the food and beverage industry. They are highly accurate and precise, making them ideal for businesses that require precise dosing of their products.

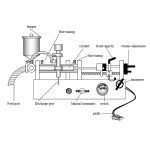

Piston Filling Machines:

These machines use a piston to fill bottles with a product. Piston filling machines are suitable for both low and high viscosity liquids and are commonly used in the food and beverage industry. They are highly accurate and precise, making them ideal for businesses that require precise dosing of their products.

How Plastic Bottle Filling Machines Work

The basic principle of all plastic bottle filling machines is to fill bottles with a specific volume or weight of product. The specific method of filling varies depending on the type of filling machine being used.

Gravity filling machines use the natural flow of gravity to fill bottles with a product. The product is poured into a hopper at the top of the machine and is then released through a filling nozzle into the bottle. The bottle is then sealed and moved to the next station for labeling and packaging.

Pressure filling machines use pressure to fill bottles with a product. The product is pumped into a holding tank and then released through a filling nozzle into the bottle. The bottle is then sealed and moved to the next station for labeling and packaging.

Volumetric filling machines use precise measurement to fill bottles with a specific volume of product. The product is poured into a hopper at the top of the machine and is then released through a filling nozzle into the bottle. The bottle is then sealed and moved to the next station for labeling and packaging.

Net weight filling machines use a load cell to weigh the product as it is being filled into the bottle. The product is poured into a hopper at the top of the machine and is then released through a filling nozzle into the bottle. The load cell measures the weight of the product as it is being filled and stops the filling process once the desired weight has been reached. The bottle is then sealed and moved to the next station for labeling and packaging.

Piston filling machines use a piston to fill bottles with a product. The product is poured into a hopper at the top of the machine and is then released through a filling nozzle into the bottle. The piston moves up and down, filling the bottle with the desired volume of product. The bottle is then sealed and moved to the next station for labeling and packaging.

Factors to Consider When Choosing a Plastic Bottle Filling Machine

Production Capacity:

The production capacity of a plastic bottle filling machine is an important factor to consider. You will need to choose a machine that can meet your production needs, without overloading or underperforming. It is important to choose a machine that can handle your current production needs, as well as any future growth.

Filling Accuracy:

The filling accuracy of a plastic bottle filling machine is another important factor to consider. You will want to choose a machine that is precise and accurate, to ensure that your products are consistently filled to the desired volume or weight.

Speed:

The speed of a plastic bottle filling machine is an important factor to consider, especially if you have a high-volume production facility. You will want to choose a machine that is fast and efficient, to help increase productivity and reduce downtime.

Ease of Use:

The ease of use of a plastic bottle filling machine is another important factor to consider. You will want to choose a machine that is easy to operate, maintain, and clean, to help reduce training time and minimize errors.

Flexibility:

The flexibility of a plastic bottle filling machine is an important factor to consider. You will want to choose a machine that is adaptable and can handle a variety of bottle sizes, shapes, and products.

Cost:

The cost of a plastic bottle filling machine is an important factor to consider. You will want to choose a machine that fits within your budget and provides the features and capabilities that you need.

Conclusion

A plastic bottle filling machine is a valuable investment for any business that manufactures and sells products in plastic bottles. There are various types of plastic bottle filling machines available, each with its own unique features and capabilities. When choosing a plastic bottle filling machine, it is important to consider factors such as production capacity, filling accuracy, speed, ease of use, flexibility, and cost. By carefully considering these factors, you can choose the right plastic bottle filling machine for your business and increase efficiency and productivity.