A phenyl filling machine is a machine that is used to fill bottles or containers with phenyl, a cleaning and disinfectant solution that is commonly used in homes, offices, and other commercial establishments. Phenyl is a highly effective disinfectant that is used to kill germs, bacteria, and other harmful microorganisms that can cause diseases. It is also used to clean and freshen up surfaces, floors, and other areas in a building.

There are several types of phenyl fillers available in the market, each designed to meet the specific needs of different users. Some of the most common types of phenyl filling machines include manual fillers, semi-automatic fillers, and fully automatic filling machines.

In this ultimate guide, we will discuss the different types of phenyl fillers, their features, benefits, and applications, and how to choose the right phenyl filling machine for your needs.

Manual Phenyl Filling Machines

Manual phenyl fillers are the most basic and affordable type of filling machines. They are ideal for small businesses and individuals who have a low volume of phenyl filling requirements. These machines are easy to operate and do not require any special skills or training.

The working principle of a manual phenyl filler is simple. It consists of a filling nozzle, a cylinder, and a valve that controls the flow of the phenyl. To fill a bottle or container, you simply place the nozzle over the opening of the container, press the cylinder, and the phenyl is dispensed into the container.

One of the main advantages of a manual phenyl filling machine is its low cost. These machines are very affordable and are a good option for those who are on a tight budget. However, manual fillers have a low filling speed and are not suitable for high volume production.

Semi-Automatic Phenyl Filling Machines

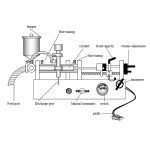

Semi-automatic phenyl filling machines are a step up from manual fillers. These machines are equipped with a filling nozzle, a filling valve, and a pneumatic cylinder that helps to control the flow of the phenyl.

To use a semi-automatic phenyl filling machine, you simply place the filling nozzle over the opening of the container, press the button, and the machine will dispense the required amount of phenyl into the container. The machine stops filling automatically when the required amount is reached.

One of the main advantages of a semi-automatic phenyl filler is its increased filling speed and accuracy. These machines are ideal for small to medium-sized businesses that have a moderate volume of phenyl filling requirements. They are also more efficient than manual filling machines and can save time and labor costs.

Fully Automatic Phenyl Filling Machines

Fully automatic phenyl fillers are the most advanced and sophisticated type of filling machines. These machines are equipped with advanced features such as a filling nozzle, a filling valve, a pneumatic cylinder, a conveyor belt, and a control panel.

To use a fully automatic phenyl filler, you simply place the bottles or containers on the conveyor belt and the machine will automatically dispense the required amount of phenyl into each container. The machine can fill multiple bottles or containers at a time, making it ideal for high volume production.

One of the main advantages of a fully automatic phenyl filling machine is its high filling speed and accuracy. These machines are ideal for large businesses and industries that have a high volume of phenyl filling requirements. They are also very efficient and can save time and labor costs.

Choosing the Right Phenyl Filling Machine

When choosing a phenyl filler, there are several factors to consider. Some of the most important factors to consider include your budget, the volume of phenyl filling required, the type of containers you will be filling, and the type of business you have.

Here are some tips to help you choose the right phenyl filling machine for your needs:

- Determine your budget: The first thing to consider is your budget. Phenyl filling machines come in different price ranges, from manual filling machines that are affordable for small businesses to fully automatic fillers that are suitable for large industries. Determine how much you are willing to spend on a filling machine and choose one that fits your budget.

- Determine the volume of phenyl filling required: The next thing to consider is the volume of phenyl filling required. If you have a small business with a low volume of filling requirements, a manual or semi-automatic filler may be sufficient. However, if you have a large business with high volume filling requirements, a fully automatic filling machine may be a better option.

- Determine the type of containers you will be filling: The type of containers you will be filling is another important factor to consider when choosing a phenyl filling machine. Some fillers are designed to fill specific types of containers, such as bottles, drums, or cans. Make sure to choose a machine that is compatible with the type of containers you will be filling.

- Determine the type of business you have: The type of business you have is also an important factor to consider when choosing a phenyl filling machine. If you have a small business, a manual or semi-automatic filler may be sufficient. However, if you have a large business with high volume filling requirements, a fully automatic filler may be a better option.

Maintenance and Safety Tips for Phenyl Filling Machines

Proper maintenance and safety are crucial to ensure the smooth functioning of your phenyl filler. Here are some maintenance and safety tips to follow:

- Regularly clean and lubricate the machine: It is important to regularly clean and lubricate the machine to ensure that it is in good working condition. This will help to prevent any wear and tear and extend the lifespan of the machine.

- Keep the machine in a dry and dust-free environment: It is important to keep the machine in a dry and dust-free environment to prevent any damage or malfunction.

- Follow the manufacturer's instructions: Make sure to follow the manufacturer's instructions for operating and maintaining the machine. This will help to ensure the safe and efficient functioning of the machine.

- Wear protective gear: It is important to wear protective gear, such as gloves and goggles, while operating the machine to prevent any accidents or injuries.

Conclusion

In conclusion, a phenyl filling machine is an essential piece of equipment for businesses and individuals that need to fill bottles or containers with phenyl. There are several types of phenyl fillers available in the market, including manual, semi-automatic, and fully automatic filling machines. To choose the right phenyl filler for your needs, consider your budget, the volume of phenyl filling required, the type of containers you will be filling, and the type of business you have. Proper maintenance and safety are also crucial to ensure the smooth functioning of your phenyl filling machine.