What is paste filling machine?

A paste filling machine is a type of automated equipment that is used to dispense, measure, and fill viscous liquids or pastes into containers or tubes. These machines are commonly used in the food, pharmaceutical, and cosmetic industries to accurately and efficiently fill containers with products such as peanut butter, honey, sauces, ointments, and creams.

Paste filling machines can be classified into different types based on the filling method, such as volumetric filling, gravity filling, and pump filling. Volumetric filling machines use a predetermined volume to dispense the paste, while gravity filling machines rely on the force of gravity to dispense the product. Pump filling machines use a piston or peristaltic pump to dispense the paste.

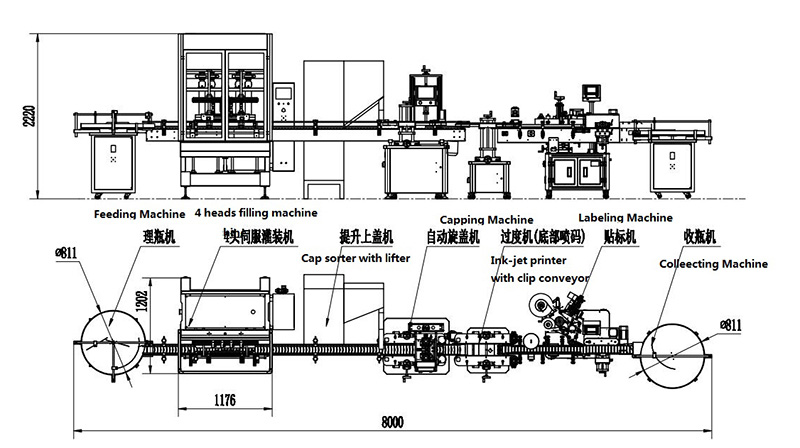

Paste filling machines can be operated manually or automatically, and can be designed for use with a variety of container sizes and shapes. Some paste filling machines also have features such as capping and labeling capabilities, and may be equipped with sensors and control systems to ensure accurate and consistent filling.

What is paste?

Paste is a thick, semi-solid substance that is typically made by mixing a fine powder or granulated material with a liquid to create a thick, cohesive mixture. Pastes can be used for a variety of purposes, including as a lubricant, adhesive, sealant, or coating.

Pastes are typically more viscous than liquids, meaning that they are thicker and have a higher resistance to flow. They may also have a higher viscosity at rest than when in motion, which makes them resistant to being poured or squeezed out of a container, but easier to spread or apply with a tool or spatula.

Pastes can be made from a wide range of materials, including metals, ceramics, polymers, and biological substances. They may be used in the production of products such as food, pharmaceuticals, cosmetics, and industrial materials. Pastes are often used in applications where it is important to control the amount of material being dispensed, or where a thick, cohesive material is required for a specific purpose.

What are the common packaging paste containers?

There are many different types of containers that can be used for packaging pastes, and the specific type of container used will depend on the properties of the paste being packaged and the intended use of the product. Some common types of containers for packaging pastes include:

Plastic tubes: Plastic tubes are a popular choice for packaging pastes because they are lightweight, easy to use, and can be sealed to prevent leakage. They are often used for products such as toothpaste, lotions, and ointments.

Glass jars: Glass jars are a durable and attractive option for packaging pastes, and are often used for products such as jams, honey, and other spreads.

Plastic bottles: Plastic bottles are a common choice for packaging pastes that are intended for use in larger quantities, such as cleaning products or industrial adhesives.

Metal cans: Metal cans are a strong and durable option for packaging pastes, and are often used for products such as paints, lubricants, and adhesives.

Pouches: Pouches are a flexible and convenient option for packaging pastes, and are often used for products such as sauces, dips, and condiments.

Regardless of the type of container used, it is important to select a container that is appropriate for the specific properties of the paste being packaged and the intended use of the product.

How to choose paste filling machine?

There are several factors to consider when choosing a paste filling machine, including:

Production volume: The production volume of the paste filling machine should be suitable for the volume of product that you need to produce. Consider the size of the machine and the speed at which it can fill containers.

Container size and shape: Make sure that the paste filling machine can accommodate the size and shape of the containers that you will be using.

Filling accuracy: It is important to choose a paste filling machine that can dispense the correct volume of paste with a high degree of accuracy. Consider the filling method (e.g., volumetric, gravity, or pump filling) and the type of control systems that are used to ensure accuracy.

Ease of use and maintenance: Consider the ease of use and maintenance of the paste filling machine, as well as the training and support that is available for operators.

Cost: Consider the overall cost of the paste filling machine, including the purchase price, operating costs, and maintenance costs.

Additional features: Consider any additional features that may be useful for your specific application, such as capping and labeling capabilities, sensors, or control systems.

It is also a good idea to research different paste filling machine manufacturers and models, and to consult with industry experts or suppliers to determine the best option for your specific needs.

What are the types of paste filling machine?

There are several types of paste filling machines, including:

Volumetric filling machines:

Volumetric filling machines dispense a predetermined volume of paste using a measuring device, such as a syringe or piston. These machines are suitable for products that are relatively consistent in density and viscosity.

Gravity filling machines:

Gravity filling machines rely on the force of gravity to dispense the paste. These machines are typically used for products with a lower viscosity, such as liquids or thin pastes.

Pump filling machines:

Pump filling machines use a piston or peristaltic pump to dispense the paste. These machines are suitable for products with a higher viscosity, and can be used to fill containers of various sizes and shapes.

Net weight filling machines:

Net weight filling machines dispense a specific weight of paste using a load cell or other weighing device. These machines are suitable for products that have a consistent density, and can provide high levels of accuracy and precision.

Auger filling machines:

Auger filling machines use a screw-like mechanism to dispense the paste. These machines are suitable for products with a high viscosity, and can be used to fill containers of various sizes and shapes.

In addition to these types of filling machines, there are also many different variations and customization options available to suit specific needs and applications. It is important to consider the specific requirements of your application when choosing a paste filling machine.

How does the paste filling machine work?

The specific operation of a paste filling machine will depend on the type of machine and the filling method being used. However, there are some general steps that are common to most paste filling machines:

Preparation:

The paste filling machine is set up and prepared for use, which may include loading the paste into the filling hopper, setting the container size and type, and adjusting the filling settings.

Container positioning:

The containers to be filled are positioned under the filling nozzle or other dispensing mechanism.

Filling:

The paste filling machine dispenses the paste into the containers using the chosen filling method. This may involve using a measuring device, such as a syringe or piston, or relying on the force of gravity or a pump to dispense the paste.

Capping:

If the paste filling machine is equipped with a capping mechanism, it will apply caps or closures to the filled containers.

Labeling:

If the paste filling machine is equipped with a labeling mechanism, it will apply labels or other markings to the filled containers.

Final inspection:

The filled containers are inspected for accuracy and quality, and any defective containers are removed.

Packaging:

The filled and labeled containers are packaged for shipping or storage.

Paste filling machines can be operated manually or automatically, and may be equipped with sensors and control systems to ensure accurate and consistent filling.

What are the advantages of paste filling machine?

There are several advantages to using a paste filling machine, including:

Increased efficiency:

Paste filling machines can fill containers much faster and more accurately than manual filling methods, which can significantly increase production efficiency.

Improved accuracy:

Paste filling machines can dispense precise volumes of paste with a high degree of accuracy, which is important for ensuring consistency and quality in the finished product.

Increased hygiene:

Paste filling machines can minimize the risk of contamination by reducing the amount of human contact with the product. This is particularly important in the food and pharmaceutical industries.

Reduced labor costs:

Automated paste filling machines can reduce the need for manual labor, which can lower labor costs and minimize the risk of errors.

Increased productivity:

Paste filling machines can operate continuously, which can significantly increase overall production capacity.

Improved safety:

Paste filling machines can reduce the risk of injuries or accidents associated with manual filling methods.

Customization:

Paste filling machines can be customized to suit specific needs and applications, with a wide range of options available for filling method, container size and shape, and additional features such as capping and labeling.

Overall, the use of a paste filling machine can help to improve the efficiency, accuracy, and quality of the filling process, and can be a valuable investment for businesses in a variety of industries.

Customize your paste filling line

If you are interested in customizing a paste filling line, there are several steps you can take:

Determine your specific needs: Consider the properties of the paste you will be filling, the size and shape of the containers you will be using, and the production volume you need to achieve. This will help you determine the type of paste filling machine and other equipment that will be most suitable for your application.

Research manufacturers and suppliers: Look for manufacturers and suppliers that offer paste filling machines and other equipment that meet your specific needs. Consider factors such as the quality and reliability of the equipment, the level of customization available, and the level of support and service offered.

Consult with industry experts: Seek the advice of industry experts or suppliers who have experience in customizing paste filling lines. They can provide valuable insights and recommendations based on your specific needs and requirements.

Consider additional features and options: Look for paste filling machines and other equipment that offer additional features and options that may be useful for your specific application, such as capping and labeling capabilities, sensors and control systems, or customization options for container size and shape.

Plan your budget: Determine the budget you have available for the paste filling line and consider the long-term costs of operating and maintaining the equipment.

Overall, customizing a paste filling line requires careful planning and consideration of your specific needs and requirements. Working with experienced manufacturers and suppliers can help ensure that you get the right equipment and features to meet your specific needs.