What is paint filling machine?

A paint filling machine is a machine that is used to fill containers with paint or other liquid coatings. These machines are commonly used in manufacturing and production environments to package and distribute paints, coatings, and other similar products. The paint filling machine is typically automated and is designed to dispense precise amounts of paint or coating into containers at high speeds. The machine may also include features such as a capping station, labeling station, and conveyor system to complete the filling and packaging process. Some paint filling machines are designed to handle a wide range of container sizes and types, while others may be specialized for specific containers. These machines are used in a variety of industries, including automotive, aerospace, construction, and more.

What is paint?

Paint is a liquid substance that is used to apply a protective or decorative coating to a surface. It is made up of a combination of pigment, binder, solvent, and additives. The pigment provides the color and hiding power of the paint, while the binder holds the pigment particles together and helps the paint adhere to the surface. The solvent is used to thin the paint and make it easier to apply, and the additives can modify the performance of the paint in various ways.

Paints are available in a wide range of colors and finishes, and they can be used on a variety of surfaces, including wood, metal, plaster, and more. There are many different types of paint, including oil-based paints, water-based paints, latex paints, and enamels. Each type of paint has its own specific properties and is suitable for different applications.

Paint is commonly applied with a brush, roller, or spray gun, and it dries to form a protective and decorative film on the surface. It is used for a variety of purposes, including to protect surfaces from damage, to improve the appearance of a surface, and to create visual effects.

What are the common packaging paint containers?

There are several common types of containers that are used to package paint, including:

- Canisters: Metal or plastic cans that are sealed with a lid or cap. Canisters are often used to package oil-based paints and other high-viscosity coatings.

- Pails: Large containers with a handle and a tight-fitting lid. Pails are often used to package large quantities of paint or coatings for industrial or commercial use.

- Jugs: Large, flexible containers with a handle and a spout for pouring. Jugs are often used to package water-based paints and other low-viscosity coatings.

- Bottles: Small, narrow containers with a neck and a cap or nozzle for dispensing. Bottles are often used to package small quantities of paint or coatings for consumer use.

- Cartridges: Small, cylindrical containers with a nozzle or spout for dispensing. Cartridges are often used to package small quantities of paint or coatings for use with specialized applicators, such as caulk guns.

- Pouches: Flexible, sealed containers that are often used to package low-viscosity coatings or paints in small quantities. Pouches can be squeezed to dispense the product.

- Drums: Large, cylindrical containers with a removable lid. Drums are often used to package large quantities of paint or coatings for industrial or commercial use.

What are the types of paint filling machine?

There are several types of paint filling machines, including:

- Gravity filler: A type of filling machine that uses gravity to dispense the product into the container. The product is placed in a hopper above the filling station, and it flows into the container through a spout or nozzle under the force of gravity. Gravity fillers are often used for low-viscosity products such as water-based paints.

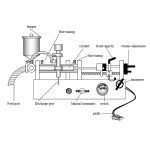

- Piston filler: A type of filling machine that uses a piston to dispense the product into the container. The piston moves up and down within a cylinder, drawing the product into the cylinder and then pushing it out through a nozzle into the container. Piston fillers are often used for thick, high-viscosity products such as oil-based paints.

- Time-pressure filler: A type of filling machine that uses a timed release of pressure to dispense the product into the container. The product is placed in a chamber, and a predetermined amount of pressure is applied to the product for a set period of time. This causes the product to flow out of the chamber and into the container. Time-pressure fillers are often used for products with medium viscosities.

- Net weight filler: A type of filling machine that dispenses the product into the container until it reaches a predetermined weight. The product is placed in a hopper, and a sensor measures the weight of the product as it is dispensed into the container. When the desired weight is reached, the filling process stops. Net weight fillers are often used for products with consistent densities.

- Volumetric filler: A type of filling machine that dispenses the product into the container until it reaches a predetermined volume. The product is placed in a hopper, and a sensor measures the volume of the product as it is dispensed into the container. When the desired volume is reached, the filling process stops. Volumetric fillers are often used for products with consistent densities.

How to choose paint filling machine?

There are several factors to consider when choosing a paint filling machine, including:

- Product characteristics: The type of paint filling machine you choose should be compatible with the characteristics of the product you are filling. For example, if you are filling a high-viscosity product such as oil-based paint, you may need a machine with a more powerful filling mechanism, such as a piston filler. If you are filling a low-viscosity product such as water-based paint, a gravity filler may be sufficient.

- Container type and size: The paint filling machine should be compatible with the containers you are using. Consider the size, shape, and material of the containers, as well as any special features they may have, such as a neck or handle.

- Filling speed and accuracy: Consider how fast the paint filling machine can fill containers, as well as the level of accuracy it can achieve. If you have a high volume of products to fill, you may need a machine that can fill containers quickly and efficiently.

- Ease of use and maintenance: Consider the ease of use and maintenance of the paint filling machine. Look for a machine that is easy to operate and clean, and that has a user-friendly interface.

- Cost: Consider the cost of the paint filling machine and its operating expenses, including maintenance and repair costs. Compare the costs of different machines to find the one that best fits your budget.

- Manufacturer and support: Consider the reputation and experience of the manufacturer, as well as the level of support they offer. Look for a manufacturer with a proven track record of producing high-quality paint filling machines and providing reliable customer support.

How does the paint filling machine work?

The operation of a paint filling machine depends on the specific type of machine you are using. Here is a general overview of how a paint filling machine works:

- The operator loads the containers to be filled onto a conveyor belt or into a filling station.

- The machine dispenses the paint or coating into the containers using a filling mechanism, such as a gravity filler, piston filler, or volumetric filler.

- The filled containers move along the conveyor belt or through the filling station to the next stage of the process, which may include a capping station, labeling station, or packaging station.

- At the capping station, the machine applies a cap or lid to the container.

- At the labeling station, the machine applies a label or other identification to the container.

- The filled and labeled containers are then packaged and shipped to their final destination.

In general, a paint filling machine is designed to dispense precise amounts of paint or coating into containers at high speeds, with minimal operator intervention. The machine may be automated or may require manual operation, depending on the specific model and application.

What are the advantages of paint filling machine?

There are several advantages to using a paint filling machine, including:

- Increased efficiency: A paint filling machine can fill containers much faster than a person can, allowing you to increase the volume of products you can produce in a given period of time.

- Improved accuracy: A paint filling machine can dispense precise amounts of paint or coating into the containers, ensuring that you are consistently producing products of the same quality.

- Reduced labor costs: A paint filling machine can operate without the need for constant supervision, allowing you to reduce the number of employees needed to fill containers.

- Increased safety: A paint filling machine can reduce the risk of accidents and injuries associated with manual filling, such as spills and splashes.

- Improved consistency: A paint filling machine can produce products that are consistently of the same quality and quantity, helping to improve customer satisfaction.

- Reduced waste: A paint filling machine can minimize waste by accurately dispensing the correct amount of paint or coating into each container.

- Increased flexibility: A paint filling machine can be adapted to fill a wide range of container sizes and types, allowing you to use the same machine for multiple products and applications.

Customize your paint filling line

If you are looking to customize a paint filling line, there are several things you can consider:

- Determine your production needs: Consider the volume of paint or coating you need to produce, as well as the size and type of containers you will be using. This will help you determine the size and capacity of the filling machine you will need.

- Choose the right filling mechanism: Select a filling mechanism that is suitable for the characteristics of your product, such as its viscosity and consistency. Options include gravity fillers, piston fillers, volumetric fillers, and more.

- Consider additional equipment: Depending on your production needs, you may want to include additional equipment in your filling line, such as a capping station, labeling station, or packaging station.

- Select a suitable conveyor system: Choose a conveyor system that can transport containers through the filling line efficiently and accurately.

- Evaluate the overall layout: Consider the layout of the filling line and how the different components will be arranged. This will help you optimize the flow of containers through the line and minimize the distance they need to travel.

- Choose the right automation level: Decide how much automation you want in your filling line. You can choose from fully automated systems, semi-automated systems, or manual systems.

- Consider the cost: Determine your budget and consider the costs of the different components of the filling line, including the filling machine, conveyor system, and any additional equipment.