What is oil filling machine?

An oil filling machine is a machine that is used to fill oil into containers. This type of machine is commonly used in the food and beverage industry, as well as in the cosmetics industry, to quickly and accurately fill containers with oil. The machine typically consists of a hopper that holds the oil, a filling mechanism, and a capping system. The filling mechanism can be either a piston-based system or a peristaltic pump. The capping system is used to securely seal the filled container.

Oil filling machines are designed to be fast and efficient, allowing for high-speed filling of a large number of containers. They are also designed to be accurate, ensuring that each container is filled to the correct level. This is important for maintaining product quality and consistency. In addition, oil filling machines are typically easy to operate and require minimal training to use.

There are many different types of oil filling machines available on the market, ranging from basic, manual machines to advanced, fully automated systems. The type of machine that is best suited for a particular application will depend on factors such as the type and viscosity of the oil being filled, the size and shape of the containers, and the production output required.

Overall, an oil filling machine is a useful piece of equipment for any business that needs to fill containers with oil. It can help to improve the speed and accuracy of the filling process, as well as ensuring that the final product is of the highest quality.

What are the common packaging oil containers?

Some common packaging containers for oil include bottles, cans, and jugs. These containers can be made from a variety of materials, including plastic, glass, and metal. The type of container that is used will depend on factors such as the type and viscosity of the oil, as well as the intended use and storage conditions for the product. For example, bottles are often used for packaging cooking oils, while cans are more commonly used for packaging motor oils. In addition, some oils may require specialized packaging containers, such as bags or pouches, to maintain their quality and stability. The packaging of oil is an important factor in the overall presentation and appeal of the product, and manufacturers often put a great deal of effort into designing attractive and functional packaging.

How to choose oil filling machine?

Choosing the right oil filling machine for your business is an important decision that can have a significant impact on the efficiency and effectiveness of your production process. There are a number of factors to consider when choosing an oil filling machine, including the type and viscosity of the oil being filled, the size and shape of the containers, and the production output required. Here are some key points to keep in mind when choosing an oil filling machine:

Type of oil: The type of oil being filled will determine the type of filling machine that is most suitable. For example, thicker oils, such as motor oil, may require a different filling mechanism than thinner oils, such as cooking oil.

Container size and shape: The size and shape of the containers being filled will also impact the type of filling machine that is needed. For example, bottles and cans have different shapes, and may require different filling mechanisms to ensure accurate filling.

Production output: The production output required will determine the speed and capacity of the filling machine needed. For high-volume production, a fully automated, high-speed filling machine may be necessary. For lower-volume production, a manual or semi-automatic filling machine may be sufficient.

Ease of use and maintenance: The filling machine should be easy to operate and maintain, with clear instructions and minimal downtime for maintenance. This will ensure maximum efficiency and productivity.

Cost: The cost of the filling machine should be considered, along with any additional costs, such as maintenance and training. It is important to balance the initial cost of the filling machine against the long-term cost savings and benefits it will provide.

Once you have considered these factors, you can begin researching different oil filling machines to find the one that best meets your needs. Some questions to consider when researching filling machines include:

- Does the filling machine have the capacity and speed needed to meet your production requirements?

- Does the filling mechanism work with the type and viscosity of the oil being filled?

- Does the filling machine have any additional features, such as a capping system or labeling system, that will be useful for your application?

- Does the filling machine have a good reputation for reliability and performance?

- Is the filling machine easy to operate and maintain?

- Does the filling machine come with training and support?

Once you have narrowed down your options, it is a good idea to request demonstrations or samples from the manufacturers to get a better sense of the performance and capabilities of the filling machines. This will allow you to make an informed decision and choose the best oil filling machine for your business.

What are the types of oil filling machines?

There are several types of oil filling machines, each with its own unique features and capabilities. These include:

Gravity fillers: As the name suggests, gravity fillers use the force of gravity to fill containers with oil. These machines are simple and easy to operate, making them a popular choice for small-scale filling operations.

Pressure fillers: Pressure fillers use a pressurized flow of oil to fill containers. These machines are typically more accurate and efficient than gravity fillers, making them a good choice for high-speed filling operations.

Piston fillers: Piston fillers use a piston-driven mechanism to dispense precise amounts of oil into containers. These machines are highly accurate and can handle a wide range of viscosities, making them a popular choice for filling a variety of oil products.

Pump fillers: Pump fillers use a pump to dispense oil into containers. These machines are often used for filling containers with viscous or thick oils that would be difficult to fill using other methods.

Net weight fillers: Net weight fillers are designed to dispense a specific weight of oil into each container. These machines are highly accurate and are often used for filling containers with high-value oil products.

In addition to these types of oil filling machines, there are also various types of filling nozzles and dispensing systems that can be used with these machines to suit different filling needs. For example, some oil filling machines may use peristaltic pump nozzles, which use a flexible tube to dispense oil, while others may use rotary or auger-style nozzles.

Oil filling machines are typically made of stainless steel or other corrosion-resistant materials to ensure durability and longevity. They are also equipped with various safety features to protect operators and prevent spills or accidents. Some oil filling machines may also be equipped with automatic controls and monitoring systems to ensure accurate and consistent filling.

Oil filling machines are used in a wide range of industries, including food and beverage, pharmaceutical, cosmetics, and chemical. They are commonly used to fill containers with products such as cooking oils, lubricants, motor oils, and other oil-based products. These machines are an essential part of many manufacturing and packaging operations, helping to ensure that products are filled accurately and efficiently.

How does the oil filling machine work?

Oil filling machines are designed to dispense precise amounts of oil into containers. These machines are typically made of stainless steel or other corrosion-resistant materials, and are equipped with various safety features to protect operators and prevent spills or accidents.

The operation of an oil filling machine typically begins with the placement of empty containers on the machine's filling platform. The machine is then turned on and the oil is fed into the machine from a supply tank or drum.

The oil is typically dispensed using a filling nozzle or dispensing system, which can be adapted to suit different filling needs. For example, some oil filling machines may use peristaltic pump nozzles, which use a flexible tube to dispense oil, while others may use rotary or auger-style nozzles.

Once the oil has been dispensed into the container, the machine will typically use a sensor or other mechanism to determine when the container is full. At this point, the filling nozzle will automatically shut off, preventing any excess oil from being dispensed.

After the container is filled, it is typically moved to a capping station, where a cap or lid is placed on the container. The machine may then use a capping mechanism to secure the cap or lid in place.

Once the capping process is complete, the filled and sealed container is moved to a packaging area, where it can be packaged and prepared for shipping.

Some oil filling machines are equipped with automatic controls and monitoring systems to ensure accurate and consistent filling. These systems may use sensors or other technology to monitor the flow of oil and make adjustments as needed to ensure that the correct amount of oil is dispensed into each container.

In addition to filling containers with oil, some oil filling machines may also be equipped with other features, such as labeling and coding capabilities, to help with the packaging and labeling of products.

Overall, oil filling machines are an essential part of many manufacturing and packaging operations, helping to ensure that oil-based products are filled accurately and efficiently.

What are the components of oil filling machine?

Oil filling machines are typically composed of several different components, each with its own specific function. These components include:

Supply tank or drum: The supply tank or drum holds the oil that will be dispensed into containers. This component is typically made of stainless steel or other corrosion-resistant materials to ensure durability and prevent contamination of the oil.

Filling platform: The filling platform is the area where empty containers are placed to be filled with oil. This component may be adjustable to accommodate different container sizes and shapes.

Filling nozzle or dispensing system: The filling nozzle or dispensing system is responsible for dispensing the oil into containers. This component may be a peristaltic pump nozzle, rotary nozzle, or other type of nozzle, depending on the specific needs of the filling operation.

Capping mechanism: The capping mechanism is responsible for securing a cap or lid onto the filled container. This component may use a variety of capping methods, such as screw-on caps, snap-on caps, or other types of closures.

Automatic controls and monitoring systems: Some oil filling machines may be equipped with automatic controls and monitoring systems to ensure accurate and consistent filling. These systems may use sensors or other technology to monitor the flow of oil and make adjustments as needed to ensure that the correct amount of oil is dispensed into each container.

Packaging area: The packaging area is where filled and sealed containers are moved for packaging and preparation for shipping. This component may include labeling and coding equipment to help with the packaging and labeling of products.

In addition to these main components, oil filling machines may also include other features and accessories, such as conveyor belts or other material handling equipment, to assist with the filling and packaging processes. Overall, the specific components of an oil filling machine will vary depending on the specific needs and requirements of the filling operation.

What are the advantages of oil filling machine?

Oil filling machines offer several advantages over manual filling methods. These advantages include:

Accuracy and precision: Oil filling machines are designed to dispense precise amounts of oil into containers, ensuring that each container is filled with the correct amount of oil. This is especially important for products that require strict adherence to volume or weight specifications.

Efficiency and speed: Oil filling machines are typically faster and more efficient than manual filling methods, allowing for higher production rates and reduced labor costs. This can be particularly beneficial for operations that require high-speed filling of large volumes of oil.

Consistency and reliability: Oil filling machines are designed to fill containers with consistent and reliable accuracy. This is important for maintaining product quality and consistency, and can help to prevent waste and product defects.

Safety and protection: Oil filling machines are equipped with various safety features to protect operators and prevent spills or accidents. This can help to ensure a safe and clean working environment, and can reduce the risk of injury or damage to equipment.

Flexibility and adaptability: Oil filling machines can be adapted to suit different filling needs and requirements. For example, they can be equipped with different types of filling nozzles and dispensing systems to handle a wide range of oil viscosities and container sizes.

Overall, oil filling machines are an essential tool for many manufacturing and packaging operations, offering accuracy, efficiency, and safety benefits that help to ensure the production of high-quality oil-based products.

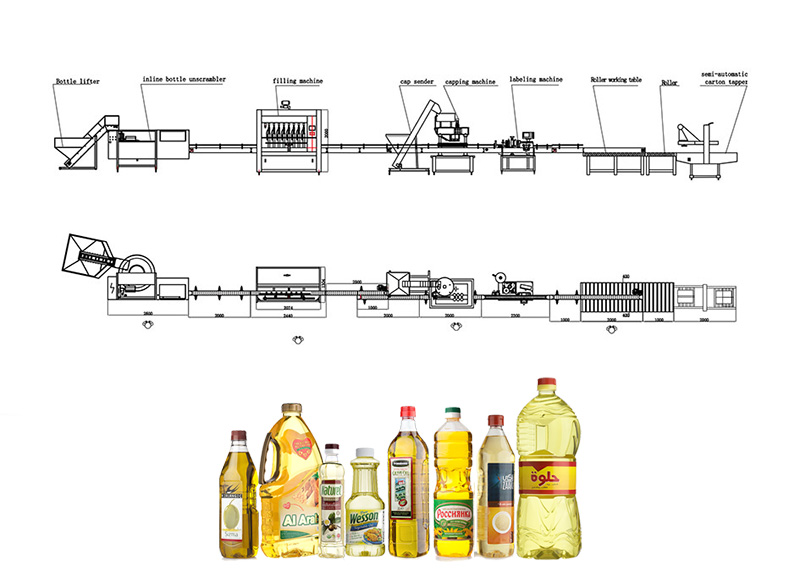

Customize your oil filling line

To customize an oil filling line, you will need to consider a variety of factors, including the type of oil being filled, the containers being used, the filling speed and accuracy required, and any additional packaging or labeling needs.

First, you will need to select the appropriate type of oil filling machine for your needs. There are several different types of oil filling machines, including gravity fillers, pressure fillers, piston fillers, pump fillers, and net weight fillers. Each type of machine has its own unique features and capabilities, so it is important to choose the right one for your specific application.

Next, you will need to select the appropriate filling nozzles and dispensing systems for your oil filling machine. These nozzles and systems can be adapted to suit different filling needs and requirements, such as the viscosity of the oil and the size and shape of the containers being used.

You will also need to consider the packaging and labeling needs of your oil-filled products. Some oil filling machines may be equipped with labeling and coding capabilities to help with the packaging and labeling of products. You may also need to select additional packaging and labeling equipment to suit your specific needs.

Finally, you will need to consider any additional equipment or accessories that may be required for your oil filling line. This may include conveyor belts or other material handling equipment to assist with the filling and packaging processes.

Overall, customizing an oil filling line requires careful planning and consideration of a variety of factors. By selecting the right equipment and accessories, you can create a customized oil filling line that is tailored to your specific needs and requirements.