A hot liquid filling machine is a type of packaging equipment that is used to fill containers with hot liquids, such as tea, coffee, soup, and sauce. These machines are commonly used in the food and beverage industry to quickly and efficiently package products for distribution and sale. In this ultimate guide, we will provide an overview of hot liquid filling machines, including their key components, types, and how they work.

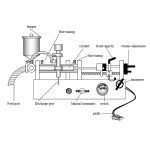

There are several key components of a hot liquid filling machine. The first is the filling nozzle, which is used to dispense the hot liquid into the container. The filling nozzle is typically made of stainless steel to resist corrosion and maintain its integrity at high temperatures.

Next, there is the filling tank, which holds the hot liquid that is to be dispensed. The filling tank is typically made of stainless steel or other food-grade materials to ensure the purity and safety of the product. The filling tank is also equipped with a heating element to maintain the temperature of the liquid.

Another important component of a hot liquid filling machine is the conveyor belt, which is used to transport the containers to and from the filling station. The conveyor belt is typically made of food-grade materials, such as plastic or rubber, to prevent contamination of the product.

The final key component of a hot liquid filling machine is the filling mechanism itself. This is the part of the machine that controls the flow of the hot liquid and ensures that it is accurately dispensed into the container. The filling mechanism may be controlled by a variety of means, including manual controls, sensors, or computerized systems.

There are several different types of hot liquid filling machines, each designed for specific applications and industries. The most common types of hot liquid filling machines include:

Inline filling machines:

Inline filling machines are the most common type of hot liquid filling machine. They are designed to fill containers as they move along a conveyor belt, allowing for high-speed and efficient filling.

Rotary filling machines:

Rotary filling machines are similar to inline filling machines, but they use a rotating turret to dispense the hot liquid into the containers. This allows for even greater speed and efficiency in the filling process.

Volumetric filling machines:

Volumetric filling machines use a specific volume measurement to dispense the hot liquid into the container. This type of filling machine is often used for products that require precise filling, such as pharmaceuticals and chemicals.

Gravity filling machines:

Gravity filling machines use the force of gravity to dispense the hot liquid into the container. This type of filling machine is typically used for products with low viscosity, such as water and juice.

Now that we have covered the key components and types of hot liquid filling machines, let's take a closer look at how they work.

The basic operation of a hot liquid filling machine involves several steps. First, the containers to be filled are placed on the conveyor belt and transported to the filling station. Next, the filling nozzle is lowered into the filling tank, and the hot liquid is dispensed into the container.

The filling mechanism then controls the flow of the hot liquid, ensuring that it is accurately dispensed into the container. Once the container is filled to the desired level, the filling nozzle is lifted out of the container, and the conveyor belt moves the container to the next station for capping, labeling, or other packaging processes.

Video From VKPAK Youtube

Hot liquid filling machines are typically designed to handle a wide range of container sizes and shapes, and they can be customized to meet the specific needs of different industries. For example, a hot liquid filling machine used in the coffee industry may be designed to handle large containers, such as pots and jars, while a hot liquid filling machine used in the soup industry may be designed to handle smaller containers, such as cans and cups.

One of the key advantages of using a hot liquid filling machine is the speed and efficiency of the filling process. These machines are capable of filling hundreds or even thousands of containers per hour, depending on their size and design. This allows for high-volume production and quick turnaround times, which is essential in the fast-paced world of the food and beverage industry.

In addition to their speed and efficiency, hot liquid filling machines are also designed to be easy to use and maintain. Most machines come with user-friendly controls and automatic cleaning systems, which help to reduce the time and effort required for daily operation and maintenance.

Another advantage of hot liquid filling machines is their ability to maintain the quality and safety of the product. These machines are typically made of food-grade materials and are designed to prevent contamination and maintain the integrity of the product. This is essential for ensuring the safety and quality of the finished product.

In conclusion, hot liquid filling machines are a vital piece of equipment in the food and beverage industry. They are designed to quickly and efficiently fill containers with hot liquids, such as tea, coffee, soup, and sauce. By providing an overview of hot liquid filling machines, including their key components, types, and how they work, this ultimate guide has provided a comprehensive overview of these essential pieces of packaging equipment.