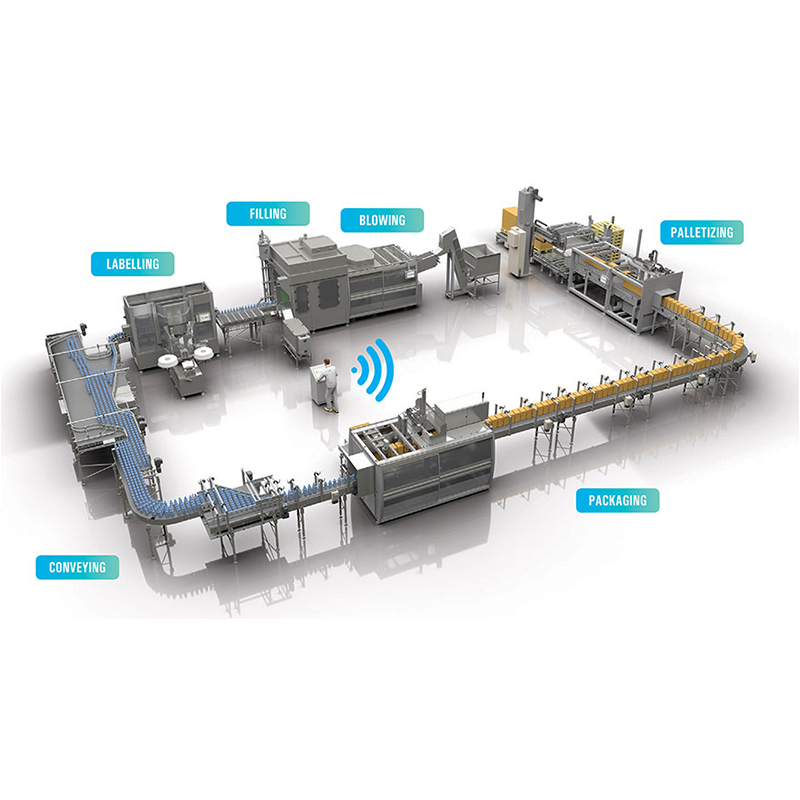

A bottling line is a series of machines and processes that are used to package a product, typically a beverage, into bottles. The process begins with the arrival of empty bottles at the start of the line, and ends with the filling, labeling, and packaging of the finished product. In between, there are a number of steps that must be carried out to ensure that the bottles are clean, properly filled, and ready for distribution.

The first step in the bottling process is usually to wash and sterilize the empty bottles. This is typically done using a machine called a bottle washer, which uses hot water and chemicals to remove any dirt or debris from the inside and outside of the bottles. The bottles are then rinsed with water and dried using hot air or steam.

Once the bottles are clean and dry, they are ready to be filled. The filling process typically involves a machine called a filler, which is used to dispense the product into the bottles. The filler is equipped with a number of filling heads, which are used to fill the bottles with the desired amount of product. The bottles are then sealed, typically using a cap or a cork.

After the bottles have been filled, they are typically labeled with information such as the product name, the ingredients, and the expiration date. This is usually done using a machine called a labeling machine, which applies the labels to the bottles as they pass through the machine.

Once the bottles have been labeled, they are ready to be packaged. This typically involves placing the bottles into boxes or other containers, and then sealing the containers for shipping. The packaging process may also involve the use of additional machines, such as shrink wrap machines, which are used to secure the bottles in place within the packaging.

In addition to the main machines and processes involved in the bottling process, there are also a number of support systems and tasks that are required to ensure that the bottling line runs smoothly. These may include maintenance and repair of the equipment, quality control checks to ensure that the bottles are being filled and labeled correctly, and the management of inventory and materials.

Working on a bottling line can be a physically demanding job, as it often involves standing for long periods of time and performing repetitive tasks. It can also be mentally challenging, as workers may need to pay close attention to the operation of the machinery and the quality of the finished product.

However, working on a bottling line can also be rewarding, as it allows individuals to be a part of a team that is responsible for producing a product that is enjoyed by many people. It can also provide opportunities for personal and professional growth, as workers may have the opportunity to learn new skills and take on additional responsibilities as they gain experience.

Overall, working on a bottling line requires a combination of physical stamina, attention to detail, and the ability to work well as part of a team. It is a crucial part of the production process for many types of products, and can provide a fulfilling and rewarding career for those who are interested in this type of work.

In a bottling line, it is important for workers to follow safety guidelines to prevent accidents and injuries. This may involve wearing protective gear, such as gloves and safety glasses, and following proper lifting techniques to avoid strain on the body.

In addition to the physical aspects of the job, bottling line workers may also be responsible for maintaining accurate records and documentation. This may include tracking the production of the product, recording the use of materials and supplies, and ensuring that all necessary paperwork is completed accurately and in a timely manner.

Depending on the size and complexity of the bottling line, there may be different levels of responsibility and job roles within the team. For example, there may be supervisors or managers who are responsible for overseeing the operation of the line and ensuring that all tasks are completed efficiently and effectively. There may also be technicians or maintenance workers who are responsible for repairing and maintaining the machinery, as well as quality control specialists who ensure that the product meets all necessary standards.

In addition to the technical skills and knowledge required for working on a bottling line, it is also important for workers to possess good communication and interpersonal skills. They may need to work closely with others in their team, as well as with other departments or functions within the company. Good communication can help to ensure that everyone is aware of their responsibilities and that the bottling line operates smoothly.

Overall, working on a bottling line can be a challenging and rewarding career path for those who are interested in the production and packaging of products. It requires a combination of technical skills, attention to detail, and the ability to work well as part of a team. With the right training and experience, individuals can take on a variety of roles within the bottling process and contribute to the success of the company.