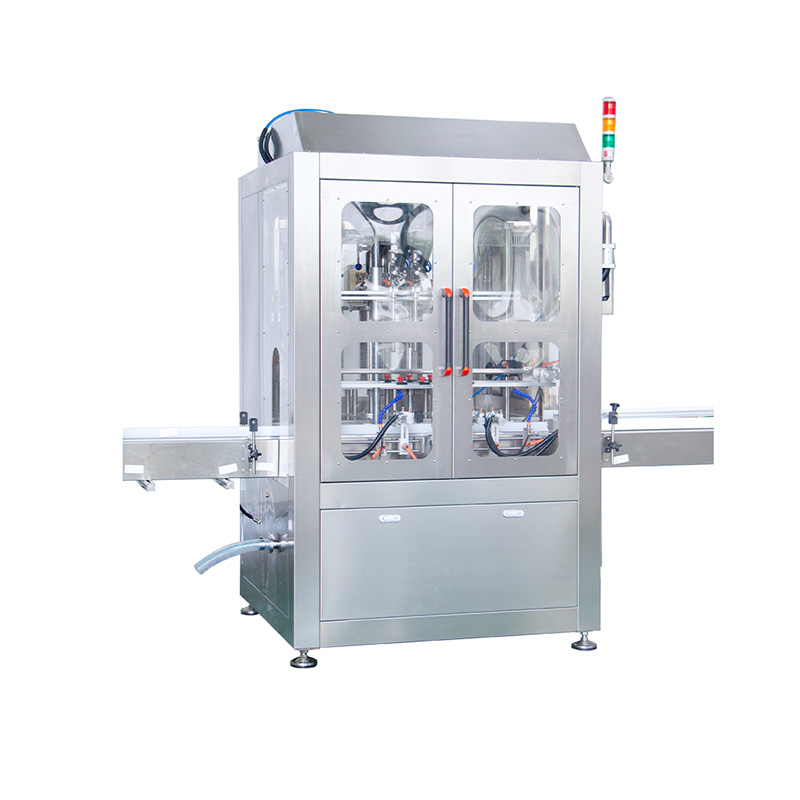

A bottle filling machine is a type of filling machine that is used in the packaging industry to fill bottles with liquids or other materials. This type of filling machine is designed to handle bottles of various sizes and shapes, and is able to dispense a precise and accurate amount of material into each bottle. Bottle filling machines are commonly used in industries such as food and beverage, pharmaceutical, and personal care. There are many different types of bottle filling machines available, including gravity filling machines, piston filling machines, and overflow filling machines. These machines use different mechanisms to dispense the material into the bottles, but all are designed to provide efficient and accurate filling.

Piston Filling Machine

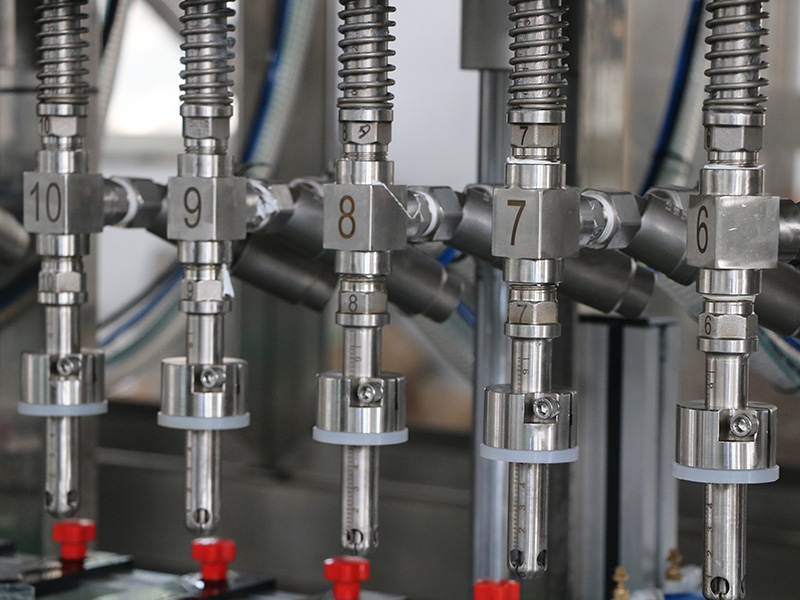

A piston filling machine is a type of machine that is used in the packaging industry to fill containers with liquids or other materials. The machine uses a piston to dispense the desired amount of material into the container, ensuring accuracy and precision in the filling process. This type of machine is commonly used in industries such as pharmaceutical, food and beverage, and personal care.

- High degree of automation, simple operation, stable operation, can effectively save enterprise costs, improve production efficiency.

- Each stand-alone machine can complete its work independently. It has independent operating system, digital control display and other electrical components to control and adjust various parameters and display settings. It can help enterprises realize standardized production

- The single machine linkage, separation fast, and adjust fast, simple, so that each production process to ensure coordination.

- Each stand-alone machine can adapt to the packaging of various specifications of bottles with few adjusting parts.

- The packaging production line adopts the international new process design, in line with GMP standards.

- The production line runs smoothly, the combination of various functions is convenient, and the maintenance is convenient

| Nozzle Number (2-16 Heads) | PCS | 6 | 8 | 10 | 12 |

| Filling volume | Ml | 100-1000ml/ 250-2500ml/500-5000ml | |||

| Production capacity | Bottle/h | 1000-3000 pcs/Hour ( Depends on Filling volume) | |||

| Quantitative error | % | ≤±1% | |||

| Voltage | V | 380V/220V, 50Hz/60Hz | |||

| Power | KW | 2.5 | 2.5 | 2.5 | 2.5 |

| Air Pressure | MPA | 0.6-0.8 | |||

| Air consumption | M3/min | 0.8 | 1 | 1.2 | 1.2 |

Overflow Filling Machine

An overflow filling machine is a type of filling machine that is used in the packaging industry to fill containers with liquids or other materials. This type of filling machine is designed to fill containers to a pre-determined level, ensuring that the containers are filled consistently and accurately. The machine uses a overflow filler mechanism to dispense the desired amount of material into the container, and the excess material is then returned to the supply tank for reuse. Overflow filling machines are commonly used in industries such as pharmaceutical, food and beverage, and personal care.

- For some highly corrosive liquid products,this machine can adapt PTFE pump,PTFE hose and sealing material, so as to avoid the corrosive of the machine

- The parts in contact with the liquid conform to the GMP standard. When filling. the filling head extends into the bottle and the bottle is sealed to ensure that the liquid does not foam and overflow, and the liquid level in the bottle is consistent

- The filling head has the function of sucking back, and there is no dripping phenomenon. The bottle is not in place and not filled, ensuring misoperation and keeping the work area clean.

- This machine has only one filling pump, one top tank and one side stand tank which can be equipped with 2~20 filling heads, and the output and filling volume can be adjusted if need.

| Name | Automatic Overflow Filling Machine |

| Measurement precision | ±0.5%-1% for 1L |

| Capacity | 800b/h-7200b/h |

| Voltage | 220VAC 50/60hz |

| Air pressure | 4~6kg/cm² |

| Air consumption | 1m/min |

| Power | 1000w |

Gravity Filling Machine

A gravity filling machine is a type of filling machine that is used in the packaging industry to fill containers with liquids or other materials. This type of filling machine uses the force of gravity to dispense the desired amount of material into the container, ensuring accuracy and precision in the filling process. The material is typically stored in a hopper or supply tank above the filling mechanism, and is dispensed into the container through a series of tubes or nozzles. Gravity filling machines are commonly used in industries such as food and beverage, pharmaceutical, and personal care.

- Suitable material: Wine, beverage,vinegar, daily chemical and something that are low viscous,especially for the foamy liquid.

- This Vertical filler is a high-tech filling equipment integrating on the PLC microcomputer programmable control, and photo electricity instruction pneumatic action.

- The machine suits for the filling of different sizes of vessel may change the filling sizes within a few minutes. Short filling circle, high production capacity.

- User may choose the filling volume and decide the filling heads per own production capacity.

- The precision time of the pneumatic valve filling may set to 0.01, second, can make the measurement precision control within ±1%, to decrease unnecessary material loss and enhance the economic efficiency.

- Each filling-head’s measurement may be individually adjusted to realize the same filling measurement.

- The machine set such function: having counting program of bottle-feeding, doesn’t fill as there is not bottle or the counting doesn’t attain a predetermined position, can start filling only when the counter records that the bottle number is same as the setting filling number.

- More or less of the filling volume, may initially adjust to the needed filling volume, then micro adjust, can get the ideal filling measurement precision.

| Nozzle Number | PCS | 6 | 8 | 10 | 12 |

| Filling volume | Ml | 100-5000 | |||

| Production capacity | Bottle/h | 1000-3000pcs(Depends on filling volume) | |||

| Quantitative error | % | 100-1000ml:≤±2% , 1000-5000ml:≤±1% | |||

| Voltage | V | AC220V 380V ±10% | |||

| Consumed power | KW | 1.5 | 1.5 | 1.5 | 1.5 |

| Air pressure | MPA | 0.6-0.8Mpa | |||

| Air consumption | M3/min | 0.8 | 1 | 1.2 | 1.2 |

Net Weight Filling Machine

A net weight filling machine is a type of filling machine that is used in the packaging industry to fill containers with liquids or other materials. This type of filling machine is designed to dispense a specific, pre-determined amount of material into each container, ensuring accuracy and consistency in the filling process. The machine typically uses a weighing mechanism to measure the weight of the material being dispensed, and will stop filling once the desired weight is reached. Net weight filling machines are commonly used in industries such as pharmaceutical, food and beverage, and personal care.

- This machine adopts PLC, touch screen control panel, convenient to adjust.

- Each filling head has the weigh and feedback system. Each filling head can be regulated.

- Photoelectric sensor, approximate switch and other electric elements are the international famous brand. No container no filling. The main host can trigger the alarm if there is any container blocked.

- Submerged filling makes it possible to reduce form. It is suitable for various kinds of filling products.

- The whole machine meets GMP standard. It is easy to disassemble clean and maintain, and the parts which contact with the filling products are made of high quality stainless steel. The whole machine is safe, environmental, sanitary, adapts to various kinds of working places.

| Nozzle Number | PCS | 2 | 4 | 6 | 8 |

| Filling volume | Ml | 5-30KG | |||

| Production capacity | Bottle/h | 100-600pcs(Depends on filling volume) | |||

| Quantitative error | % | ≤±2% | |||

| Voltage | V | AC220V 380V ±10% | |||

| Consumed power | KW | 1.5 | 1.5 | 1.5 | 1.5 |

| Air Pressure | MPA | 0.6-0.8Mpa | |||

| Air consumption | M3/min | 0.8 | 1 | 1.2 | 1.2 |

Servo Pump Filling Machine

A servo pump filling machine is a type of filling machine that is used in the packaging industry to fill containers with liquids or other materials. This type of filling machine uses a servo motor to drive a pump, which is responsible for dispensing the desired amount of material into the container. The servo motor allows for precise and accurate control of the filling process, ensuring that the containers are filled consistently and accurately. Servo pump filling machines are commonly used in industries such as pharmaceutical, food and beverage, and personal care.

- Rotary lobe pump (liquid contact parts in SUS316 or Teflon).

- Stainless steel SUS 304 filling nozzle.

- Shut off filling nozzle with pneumatic valve to prevent dropping.

- Each filling pump driven by a variable speed Servo motor individually.

- Dipping type filling nozzle, no spilling of liquid onto clean bottles and conveyor.

- Filling nozzle holding device and uplift assembly with a huge solenoid valve.

- Stainless steel drip tray to keep liquid from spilling onto the clean bottles.

- Empty bottles feeding index gate and filled bottles relaxing index gate.

- Pneumatic control system for index gates.

- Photocell sensors (Japan OPOTEX brand)

| Voltage | 220 volts, single phase, 60/50 Hz(can be customized) |

| Filling range | 50ml-5000ml (more than 5000ml can be customized) |

| Filling accuracy | ± 0.5% |

| Air source pressure | 0.6-0.8 MPa |

| Filling speed | about 50 bottles per minute (6 nozzles filling machine 1000 ml capacity) |

| Filling Nozzle | 2/4/6/8/12/16(can be customized) |

Anti-Corrosion Filling Machine

An anti-corrosion filling machine is a type of filling machine that is designed to prevent the corrosion of the machine itself, as well as the containers being filled. This type of machine is typically used to fill containers with corrosive liquids or other materials, and is designed with corrosion-resistant materials and coatings to protect the machine from damage. In addition to protecting the machine, an anti-corrosion filling machine may also use special filling nozzles or other components to prevent the corrosive material from coming into contact with the container itself. This type of filling machine is commonly used in industries such as chemical, pharmaceutical, and agricultural.

- Filling by gravity. If has foam, diving filling system and Install a stopper in filling nozzles, which works like a stopper in wine bottle, surely no dripping.

- Is widely used to fill corrosive liquid into straight neck bottles. Also one set machine, can be used to fill oblique neck bottle, only need to change a plate, very convenient.

- Can fill corrosive liquid both with Viscosity or not, need to add piston device for liquid in viscosity .

- Also other models in different quantity of filling heads (6, 8, 10, 12, or more)

- Made of PP material. Newest design in structure, More stronger for anti-corrosive and 100% percent no liquid leaking. PP is the best material for anti-corrosive function, much better and stronger than PVC and stainless steel.

- Filling range: 1000ML (filling volume can be set through touch screen)

- Filling accuracy: ±1%

- Filling speed: 1 .5circles per minute.

- Working air pressure: 6-7kg/c㎡

- Operation voltage: 220V (available to be customized)

Continuous Pump Filling Machine

A continuous pump filling machine is a type of filling machine that is used in the packaging industry to fill containers with liquids or other materials. This type of filling machine uses a pump to dispense the material into the container, and is designed to operate continuously without the need for operator intervention. The machine is able to fill a large number of containers in a short amount of time, making it ideal for high-volume production environments. Continuous pump filling machines are commonly used in industries such as pharmaceutical, food and beverage, and personal care.

- This machine adopts optical fibers to track bottle for high speed and high efficiency filling, and there is no break in the production process.

- It is suitable for daily chemical liquid paste filling such as shampoo, shower gel, disinfectant, hand sanitizer and detergent.

- Fully automatic operation, bottle entry, positioning, filling and bottle exit are automatically controlled by PLC, and the whole process meets GMP standards.

- According to the characteristics of different products, we can provide piston, rotor pump, flowmeter, solenoid valve and other measurement methods.

For different types bottle of different heights and capacities, especially special-shaped bottles, it only takes 3-5min to complete the commissioning. - It solves the problems of time-consuming and laborious due to a wide variety, small number of single products and frequent machine adjustment. At the same time, it is suitable for mass production.

| Container size | 100ml to 5000m | ||||||

| Nozzles available | 2 to 4 | ||||||

| Overall dimensions | 1800mm*1300mm*2000mm | ||||||

| Air consumption | 2 to 4 | ||||||

| Electrical | 220 V 50/60hz single phase | ||||||

| Power | 3.5KW | ||||||

| Production rate | 40 to 50 Containers/Minute | ||||||

A bottle filling machine is a type of filling machine that is used in the packaging industry to fill bottles with liquids or other materials. This type of machine is designed to handle a wide range of bottle sizes and shapes, and is able to dispense a precise and accurate amount of material into each bottle. Bottle filling machines are commonly used in industries such as food and beverage, pharmaceutical, and personal care.

There are many different types of bottle filling machines available on the market, each with its own unique features and capabilities. The type of machine that is right for a particular application will depend on the specific requirements of the filling process, including the type of material being filled, the size and shape of the bottles, and the desired output rate. In this ultimate guide, we will provide an overview of the different types of bottle filling machines available, as well as their features and benefits.

Gravity Filling Machines

Gravity filling machines are one of the most common types of bottle filling machines. These machines use the force of gravity to dispense the material into the bottles, and are typically used to fill bottles with low to medium viscosity liquids. Gravity filling machines are often used in industries such as food and beverage, pharmaceutical, and personal care.

One of the main advantages of gravity filling machines is their simplicity and ease of use. These machines do not require any special training or expertise to operate, and are able to fill bottles quickly and accurately. Additionally, gravity filling machines are typically less expensive than other types of filling machines, making them a cost-effective solution for many applications.

Gravity filling machines typically consist of a hopper or supply tank that holds the material to be filled, a series of tubes or nozzles that dispense the material into the bottles, and a filling mechanism that controls the flow of material. Some gravity filling machines also include features such as flow control valves and level sensors to ensure accurate and consistent filling.

Piston Filling Machines

Piston filling machines are another common type of bottle filling machine. These machines use a piston to dispense the material into the bottles, and are able to handle a wide range of viscosity levels. Piston filling machines are often used in industries such as pharmaceutical, food and beverage, and personal care.

One of the main benefits of piston filling machines is their accuracy and precision. The piston mechanism allows the machine to dispense a precise and consistent amount of material into each bottle, ensuring that the filled containers meet the required specifications. Additionally, piston filling machines are able to handle a wide range of viscosity levels, making them suitable for a variety of materials.

Piston filling machines typically consist of a supply tank that holds the material to be filled, a piston that dispenses the material into the bottles, and a filling mechanism that controls the flow of material. Some piston filling machines also include features such as flow control valves and level sensors to ensure accurate and consistent filling.

Overflow Filling Machines

Overflow filling machines are a type of bottle filling machine that is designed to fill containers to a pre-determined level. These machines use an overflow filler mechanism to dispense the material into the bottles, and the excess material is then returned to the supply tank for reuse. Overflow filling machines are commonly used in industries such as pharmaceutical, food and beverage, and personal care.

One of the main advantages of overflow filling machines is their ability to fill containers consistently and accurately. The overflow filler mechanism ensures that the containers are filled to the same level every time, eliminating the need for manual adjustments or corrections. Additionally, the reuse of excess material helps to reduce waste and improve efficiency.

Net Weight Filling Machines

Net weight filling machines are a type of bottle filling machine that is designed to dispense a specific, pre-determined amount of material into each container. These machines use a weighing mechanism to measure the weight of the material being dispensed, and will stop filling once the desired weight is reached. Net weight filling machines are commonly used in industries such as pharmaceutical, food and beverage, and personal care.

One of the main benefits of net weight filling machines is their accuracy and consistency. The use of a weighing mechanism ensures that the correct amount of material is dispensed into each container, reducing the risk of over or under filling. Additionally, the ability to dispense a specific amount of material can help to ensure that the filled containers meet regulatory requirements.

Net weight filling machines typically consist of a supply tank that holds the material to be filled, a weighing mechanism that measures the weight of the material being dispensed, and a filling mechanism that controls the flow of material. Some net weight filling machines also include features such as flow control valves and level sensors to ensure accurate and consistent filling.

Servo Pump Filling Machines

Servo pump filling machines are a type of bottle filling machine that uses a servo motor to drive a pump, which is responsible for dispensing the material into the bottles. The use of a servo motor allows for precise and accurate control of the filling process, ensuring that the containers are filled consistently and accurately. Servo pump filling machines are commonly used in industries such as pharmaceutical, food and beverage, and personal care.

One of the main advantages of servo pump filling machines is their ability to fill containers at high speeds while maintaining accuracy and precision. The servo motor allows the machine to quickly and accurately dispense the material into the bottles, making it suitable for high-volume production environments. Additionally, the use of a servo motor helps to reduce the amount of wear and tear on the machine, increasing its longevity and reliability.

Servo pump filling machines typically consist of a supply tank that holds the material to be filled, a servo motor that drives the pump, and a filling mechanism that controls the flow of material. Some servo pump filling machines also include features such as flow control valves and level sensors to ensure accurate and consistent filling.

Anti-Corrosion Filling Machines

Anti-corrosion filling machines are a type of bottle filling machine that is designed to prevent the corrosion of the machine itself, as well as the containers being filled. These machines are typically used to fill containers with corrosive liquids or other materials, and are designed with corrosion-resistant materials and coatings to protect the machine from damage. In addition to protecting the machine, anti-corrosion filling machines may also use special filling nozzles or other components to prevent the corrosive material from coming into contact with the container itself. Anti-corrosion filling machines are commonly used in industries such as chemical, pharmaceutical, and agricultural.

One of the main benefits of anti-corrosion filling machines is their ability to handle corrosive materials without damaging the machine or the containers. The use of corrosion-resistant materials and coatings ensures that the machine will remain operational even when filling corrosive materials, reducing downtime and maintenance costs. Additionally, the use of special filling nozzles or other components can help to prevent the corrosive material from damaging the containers, ensuring that the filled products are of high quality.

Anti-corrosion filling machines typically consist of a supply tank that holds the material to be filled, a filling mechanism that dispenses the material into the bottles, and special components such as corrosion-resistant materials and filling nozzles. Some anti-corrosion filling machines also include features such as flow control valves and level sensors to ensure accurate and consistent filling.

Continuous Pump Filling Machines

Continuous pump filling machines are a type of bottle filling machine that uses a pump to dispense the material into the bottles, and is designed to operate continuously without the need for operator intervention. These machines are able to fill a large number of containers in a short amount of time, making them ideal for high-volume production environments. Continuous pump filling machines are commonly used in industries such as pharmaceutical, food and beverage, and personal care.

One of the main benefits of continuous pump filling machines is their high output rate. These machines are able to fill a large number of containers in a short amount of time, making them suitable for high-volume production environments. Additionally, the continuous operation of the machine helps to reduce downtime and improve overall efficiency.

Continuous pump filling machines typically consist of a supply tank that holds the material to be filled, a pump that dispenses the material into the bottles, and a filling mechanism that controls the flow of material. Some continuous pump filling machines also include features such as flow control valves and level sensors to ensure accurate and consistent filling.

In conclusion, bottle filling machines are an essential piece of equipment in the packaging industry, and are used to fill bottles with liquids or other materials. There are many different types of bottle filling machines available, each with its own unique features and capabilities. The type of machine that is right for a particular application will depend on the specific requirements of the filling process, including the type of material being filled, the size and shape of the bottles, and the desired output rate. By understanding the different types of bottle filling machines and their features and benefits, you can choose the right machine for your application and achieve consistent and accurate filling results.